Production Module Features

Madiwor provides a Production module with a series of functions to assist the manufacturing process specific to this industry.

Once the sales order is generated, the production department receives a Sales Order with all the SKUs to be manufactured. All the main characteristics of the label are already specified and loaded in the application when the SKU was created. Madiwor will allow us at this point to complete the SKU with the production data. For example assigning a die cut. As well as the possibility to attach SKU´s art file and any additional information to the label.

Production Job Management

All production jobs are stored and can be retrieved at any moment. Productions Jobs can be also printed in case you need to provide a copy to the operator or choose to browse it digitally in a computer or mobile device.

Re-sale Products Orders

In case your company provides integrated solutions including barcode printers and thermal transfer ribbons Madiwor offers a solution to manage these SKUs as well. Sales Orders containing these product will generate not a production job but a re-sale order. This will appear pending to dispatch in the dispatch module until this arrive or are retrieved from stock.

Production SKUs

Production SKUs provide the production department the ability to specify all the necessary details specific to the equipment or die cut that the job will require. Once the information is loaded, it will be kept in the database so that the every repetition will automatically load the SKU configuration.

Daily Reports

Using the daily reports functionality operators are able to inform the work done for each production job. The user interface is very intuitive and hides the operator through the corresponding option to describe the job progress each day. With this information plus the material consumption it is possible to analyze the performance of the operator, the machines and the impact into the profit of an SKU.

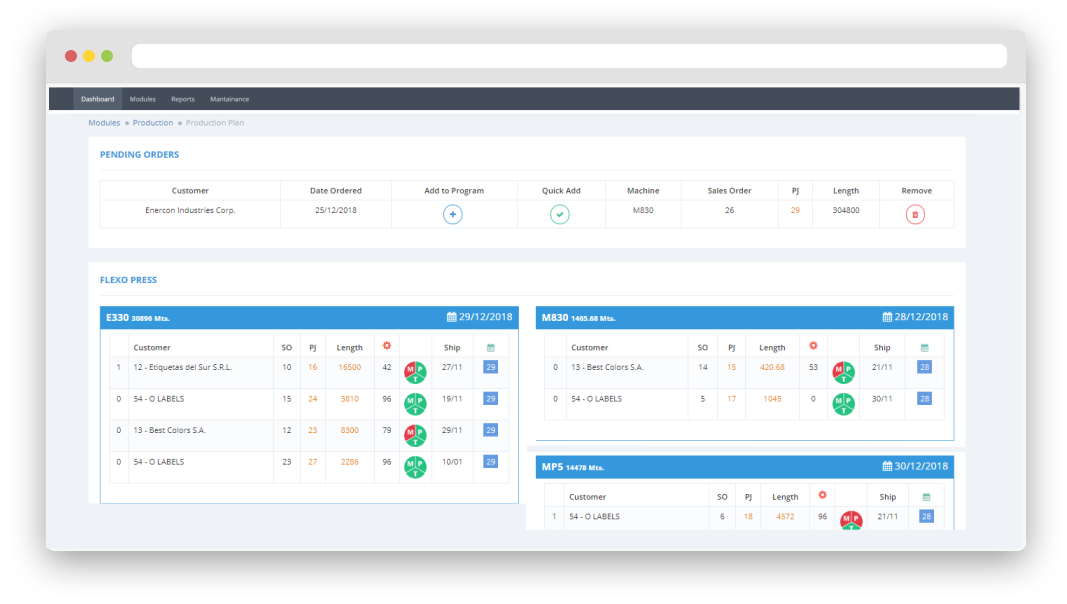

Production Planning

Using the production plan is very easy and intuitive to organize an view the production orders ready for production. The Production plan will show all the production equipment available. Based on the SKU information Madiwor knows in which press, finishing or other machine this product will good through. This will allow you to add it automatically to the machine queue. You can also change this manually and organize the production plan using the drag & drop between presses. In the same view you can monitor the status of the material, die cut and art for the SKU.

Real Time Dashboard

Using the Madiwor IOT devices you can monitor in real time your presses or most of production equipment. You can check the current speed, average speed, production time and material processed. Additionally you can generate custom reports by date and equipment.

Press Management

Using the Settings for this module you can setup all you production equipment. This is a very important task that will allow you to visualize the machines in the production plan. Also here you are able to enter the cost related to each machine. This is essential for later when making price calculations or analyzing the costs of an SKU.

Machine Capabilities

UIn order to align to your equipment configuration Madiwor offers the machine capabilities functionality. By adding capabilities and assigning it to a machine you can then plan process the label manufacturing accordingly. Moreover capabilities incorporate cost management so as to be able to impact the cost analysis and price calculations.

Module Highlights

Production Module

Production Planning, Daily Reports, Production Jobs Management

The user interface is extremely easy and intuitive. The production plan shows a colored graph where you can quickly visualize the general status of the resources required for each work order. By automating the update of this indicator, Madiwor fully enhances the communication within the company.

Raw Material Inventory

Raw Material Inventory, Roll Cut & Traceability

The great thing about this module is the not only it allows you to cut rolls into the size required by each order but, it lets you have them assigned to a production job or to the stock. This reduces scrap, saves time when retrieving inventory and automates the need to trace any material used.

Accelerate productivity

Our software is specially designed to be intuitive and easy to use.

It assists your organization in key processes. Madiwor understands the challenges and provides the best solution.

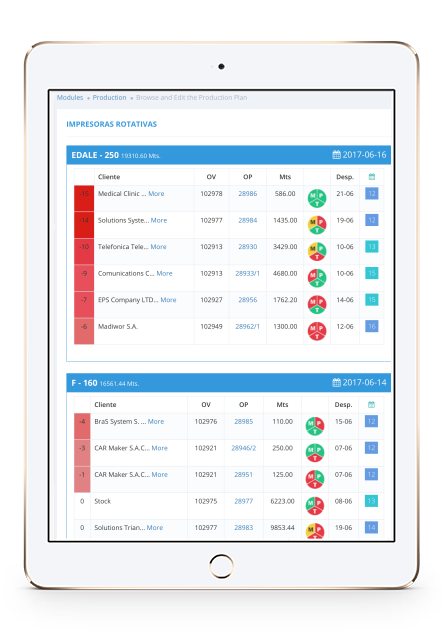

Cross-Platform

Madiwor provides perfect and flawless compatibility between all platforms.

Mobile

Madiwor turns your mobile device into your portable production office. You can browse production jobs, check for new sales orders to produce, monitor in real time your presses or check the dashboards no matter where you are.

Get Time On Your Side

Saves time needed for setup and training. Madiwor is already running.

Minimum Training

Easy to Use. Intuitive modularity improving the user experience.

Eliminate time Consuming Tasks

Eliminates the burden of upgrading, maintenance, and safeguarding data.

Increase Efficiency

Cuts operational costs. Plus Madiwor costs less compared to on-premises systems.